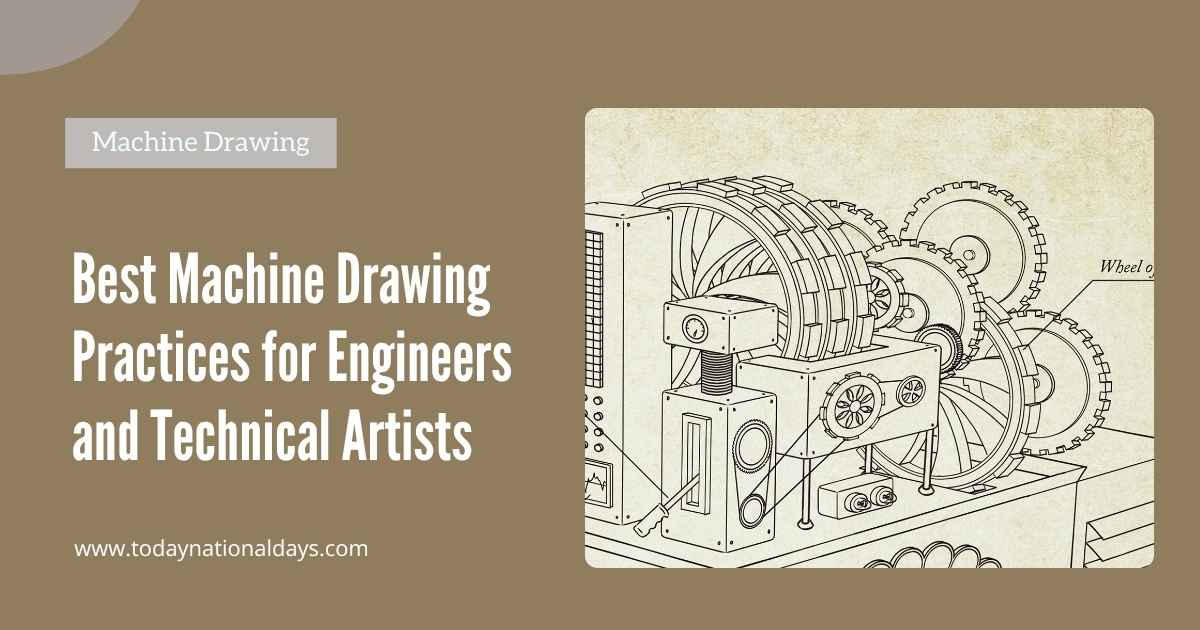

Machine drawing is a specialized branch of technical art that visually communicates the specifications and functioning of mechanical components. Commonly used in engineering, design, and manufacturing fields across the USA, this discipline plays a critical role in turning concepts into buildable products. Whether it’s a gearbox, valve system, or structural frame, machine drawings act as the blueprint that guides fabrication, inspection, and maintenance.

A well-prepared machine drawing ensures precision and consistency across teams—from engineers and draftsmen to machinists and quality control departments. This blog post offers practical insights for students, professionals, and industrial artists who want to deepen their expertise in producing machine drawings with clarity, accuracy, and professionalism.

Top Types of Machine Drawing Used in Engineering Projects

Machine drawing includes several categories, each suited for a different stage in the design and manufacturing process. These types help engineers break down a mechanical concept into understandable and actionable parts.

- Assembly Drawing

Shows how various components fit together to form a complete machine. It includes part labels, reference numbers, and sectional views for interior details. - Part Drawing (Component Drawing)

Illustrates individual machine parts separately, including complete dimensional information, tolerances, surface finish, and material specifications. - Exploded View Drawing

Displays all components separated but aligned in their order of assembly. It’s widely used in instruction manuals and maintenance guides.

Each type of drawing requires specific symbols, line types, and annotation practices. Adherence to ISO or ANSI standards is crucial, especially when products are being manufactured internationally. Design errors caught during the machine drawing stage can prevent costly rework, making this step not only artistic but economically vital.

Table: Comparison of Machine Drawing Types and Uses

| Drawing Type | Description | Common Use Case | Includes Sections | Example Industries |

|---|---|---|---|---|

| Assembly Drawing | Complete layout of a machine with labeled parts | Manufacturing & inspection | Often | Automotive, Robotics |

| Part Drawing | Isolated view of one component with dimensions | Fabrication & machining | Sometimes | Aerospace, Tools |

| Exploded View | Disassembled parts shown in sequence | Repair manuals, training guides | Rare | Consumer Goods, Hardware |

| Schematic Diagram | Symbols and flowpaths instead of physical shapes | Hydraulic, pneumatic, or wiring logic | No | Electrical, HVAC |

| Sectional View | Cut-through view of internal machine elements | Understanding internal mechanisms | Always | Heavy Equipment, Motors |

Proper understanding of these drawing formats makes an engineering artist more versatile and increases design communication efficiency.

Core Elements That Define a Quality Machine Drawing

To produce effective machine drawings, it’s not enough to sketch parts—you must follow structured drafting principles that ensure accuracy and functionality. Professionals in Canada and Australia frequently apply these practices to meet global compliance standards in production and quality control.

1. Dimensional Accuracy and Tolerances

All dimensions must be clearly indicated, including overall size, hole placements, and depth cuts. Tolerances should be assigned using industry formats such as unilateral, bilateral, or geometric tolerancing methods (GD&T) to allow slight variations without affecting performance.

2. Line Types and Symbols

Different line styles serve different purposes—solid lines for visible edges, dashed lines for hidden features, center lines for symmetrical components. Standard symbols are used to denote surface finish, welding joints, thread types, and bearings.

3. Material and Finish Annotations

Material specification is a vital part of any machine drawing. Noting steel grade, surface hardness, or aluminum alloy can impact machinability and lifespan. Surface finish indicators (Ra values) show how smooth a surface must be for its intended use.

Correctly applying these elements ensures the drawing can be interpreted accurately by everyone from CNC operators to assembly technicians.

Best Software Tools for Creating Machine Drawings

Modern engineers create machine drawings using specialized CAD software, ensuring precision and enabling effortless revisions. These platforms are the industry standard for generating production-ready blueprints.

- AutoCAD Mechanical

Widely used for 2D machine drafting. It includes libraries for bolts, nuts, washers, and standard part templates which speeds up technical detailing. - SolidWorks

Ideal for 3D modeling and generating 2D machine drawings from solid models. It’s commonly used in the USA and known for parametric modeling and assembly simulation. - Fusion 360

Offers cloud-based tools for collaborative mechanical design. Features built-in CAM and simulation capabilities, making it suitable for both design and manufacturing engineers. - CATIA

Preferred in aerospace and automotive sectors. Its advanced surface modeling and multi-platform integration make it a top-tier choice for large engineering projects.

Learning any of these tools provides an edge in the job market and helps technical artists turn sketches into universally readable engineering documents.

Practical Applications of Machine Drawing in Industry

Machine drawing is not a purely academic exercise. It has widespread real-world applications across multiple industries, directly impacting product development, safety, and cost-efficiency.

Manufacturing and Prototyping

Accurate drawings guide CNC machines, create molds, and cut raw materials in manufacturing. They serve as the foundation for tolerancing checks, heat treatment procedures, and part inspections.

Equipment Maintenance and Repair

Maintenance teams rely on exploded view drawings and assembly sheets to disassemble, repair, and reassemble complex machinery. Diagrams help identify worn components and order exact replacements.

Industrial Design and Innovation

Before patenting or prototyping a new machine, designers submit technical drawings that show feasibility and part interactions. These documents are essential for approval, budgeting, and compliance testing.

In all these applications, machine drawings act as a common language—bridging communication between designers, engineers, technicians, and management teams.

Common Mistakes to Avoid in Machine Drawing Drafts

Even experienced professionals sometimes overlook important drafting fundamentals. Awareness of common mistakes helps maintain clarity and professional standards.

Overcrowding Dimensions

Placing too many dimension lines in a small area can make a drawing unreadable. Always leave spacing between measurements and ensure arrows don’t overlap.

Using Inconsistent Units

Mixing imperial and metric units without clear labeling can cause catastrophic errors in fabrication. Stick to one unit system and note it clearly on every sheet.

Missing Part Numbers or Notes

Every component must have a reference number and description. Omitting this can slow down procurement and assembly or result in part mismatches.

By maintaining consistency and adhering to ISO/ANSI standards, your drawings will remain clear and production-ready—regardless of who is reading them.

Final Thoughts on Mastering Machine Drawing for Professional Use

Machine drawing remains one of the most essential tools in the engineering and manufacturing workflow. It brings together precision, visual communication, and industry compliance to convert ideas into tangible products. Whether you’re based in the UK, the USA, or Australia, learning the correct techniques and tools ensures your drawings speak a universal technical language.

From the simplest washer to the most complex robotic arm, every machine begins as a drawing. Mastering this skill means becoming an indispensable link in the chain of modern industrial art and engineering.

FAQ About Machine Drawing

Is machine drawing the same as engineering drawing?

Not exactly. Engineering drawing is a broader field. Machine drawing specifically refers to drawings that represent machine parts and assemblies.

Can machine drawings be done manually?

Yes, manual drafting is still taught and used in some schools. However, CAD software is the industry standard due to its accuracy and speed.

What is the most important part of a machine drawing?

Dimensional accuracy and clarity. If a machinist can’t read or measure it clearly, it’s not a usable drawing.

Are 3D models enough, or are 2D drawings still needed?

2D drawings are still necessary for manufacturing, especially for detailing dimensions, tolerances, and material notes.

Which industries rely most heavily on machine drawing?

Aerospace, automotive, defense, electronics manufacturing, and heavy machinery sectors all depend heavily on machine drawing.